CHAPTER XIII

Looking Ahead to the Continent

Detailed engineer planning for a Continental invasion continued in 1943 with the addition of a forecasting technique imposed upon theater planners by ASF headquarters in Washington. To involve theater staffs around the world in procurement planning for major operations Army Service Forces had devised a system of so-called operational or keyed projects. Theater planners were to compile lists of Class IV and Class II items (in excess of regular TOE and TBA allotments) and to key the requested items to specific and foreseeable tasks such as the reconstruction of an individual port.

On 4 June 1943, the War Department directed ETOUSA to begin studying what equipment would be needed for an invasion of the Continent. These studies were known in England as Projects for Continental Operations, or PROCO. Their objective was to allow ASF ample time to procure from American industry major items of machinery and specialized equipment and have them on hand in the New York Port of Embarkation for shipping as theater users requested them. The forecasting system required detailed information on numbers of items needed, intended use, tonnage estimates, and operational justification. Not intended as requisitions in themselves, the project requirement statements went directly to the War Department for action. The PROCO system produced some successes but in many ways ran afoul of realities and practices in the theater.1

Engineer PROCO Projects

Engineer PROCO studies began with some confusion. When the technical services involved in PROCO planning began their work, formal Allied agreement to the OVERLORD concept was still three months away. Upon receiving word of the War Department's requirements, General Moore protested that he needed basic data on eight separate aspects of the forthcoming operation in order to proceed with operational or keyed planning. Specifically, his engineer staff needed to know the maximum size of the assault force, the approximate size of forces expected to be employed on the Continent on D plus 90, maximum forces to be employed in active operations, the number of lines of communications, the number of ports to be built or rebuilt, the number of airfields required in each calendar quarter through the end of 1944, the state

[277]

of repair of facilities in France, and an evaluation of areas to be occupied on the Continent as of the end of 1944. While American engineer members of COSSAC gathered some of the data, General Lee provided the basis of engineer supply planning for the majority of PROCO projects on 24 June.2

In a letter of instruction to his subordinate SOS elements Lee listed the objectives for what he described as a ROUNDUP-type operation. American forces ashore in France by D plus 30 would number 480,000; 985,000 were expected by D plus 90. To support this strength, two one hundred-mile-long lines of communications were to be operating by D plus 90, and by D plus 240, or the end of 1944, the lines were expected to be two hundred miles long. On D plus 90 two additional lines of communications were to open to receive supplies shipped directly from the United States to the European mainland. The overall plan called for four major and eight minor ports to be fully operational by D plus 240. On these assumptions the engineers worked all summer, with each division of the theater engineer's office responsible for its assigned portion of the thirty categories of engineer functions represented in the PROCO statements. They divided delivery schedules according to the planning timetable General Lee had described, earmarking matériel for shipment in the first ninety days after the invasion or for D plus 91 to D plus 240. With D-day later set tentatively for 1 May 1944, the engineers wanted to have 75 percent of the equipment and supply for the first ninety-day phase on hand in the United Kingdom by 1 January 1944. Matériel for the second period was to be in the theater ninety days before it was needed. By late September, they had sent to Washington twenty-eight studies with tonnage estimates totaling 1,136,713 long tons.3

Differing views on the purpose of PROCO and on the proper content of PROCO studies also fueled lively correspondence between the theater and the War Department through the summer. In late June 1943 General Lee asserted that requisitions for the material listed in the theater PROCO studies would be appended to those studies. Though this was not the original scheme for the keyed projects, the War Department acquiesced in the procedure on 25 July. In September the War Department complained about the content of some of the submitted studies, citing especially quartermaster PROCO submissions for medals and decorations, breadsacks, and standard two-inch plugs for gasoline cans. The engineers' submissions conformed to the letter and the spirit of the ASF program, but engineer planners often neglected to identify those items that could be procured in England through reverse lend-lease. Though these items were to be included in the studies, the PROCO procedures called for flagging them with asterisks in the material lists. Once the British had supplied the items, the theater would notify the War Department to cancel them in the PROCO studies.4

In Washington, engineer PROCO projects followed a tortuous path. From

[278]

the War Department adjutant general they went to the director of plans and operations, AS17, who was responsible for control until the projects were approved. The director of plans, AS17, sent the studies to the Logistics Group, Operations Division, War Department General Staff, which determined whether the projects were necessary. The director of plans, ASF, next forwarded the studies to OCE, WD. OCE decided whether each project was necessary and adequate, from both technical and tactical standpoints. OCE then edited the bill of materials based on availability and corrected all nomenclature and catalogue numbers. The director of plans, ASF, then sent the projects to the director of the Requirements Division, AS17, who determined whether the requirements fitted into worldwide plans for each item or whether the Army Supply Program would have to be changed. The projects again went through the director of plans, ASF, to the Logistics Branch, OPD, for approval and finally to G-4, War Department General Staff, for concurrence. The approved projects then became the basis upon which the engineers in the United Kingdom requisitioned Class IV items from the United States.5

Confusion existed for a time at the New York Port of Embarkation because ETOUSA included in PROCO tonnage figures all of the Class IV operational needs estimated before PROCO began. NYPOE, on the other hand, had accounted only for tonnages submitted as PROCO projects. Wide discrepancies in the records of shipments ASF, NYPOE, and ETOUSA maintained added to the confusion. For example, ASF figures included items released for shipment to the United Kingdom. ASF considered them delivered, but these figures were meaningless to the engineers in the United Kingdom because some time elapsed between the date items were released in the United States and their arrival in theater. As late as March 1944 the OCE Supply Division estimated that 120 days were required for delivery of supplies from the United States after requisitions had been placed, assuming the supplies were actually available in U.S. Army depots. Therefore the division felt it was necessary to provide the United States with estimates of Class IV supplies required for the next fifteen months.6

By the end of April 1944, shipments of engineer supplies from the United States, particularly materials requested under PROCO, were seriously behind schedule-a backlog of 320,278 long tons existed. The situation improved only somewhat during May, with 246,521 long tons still overdue. Meanwhile, engineer projects had been placed in a common pool with all others. Supplies and equipment were issued based on established priorities to organizations having approved projects whether or not the specific supplies had arrived. Along with other services and commands the engineers were given a credit and a priority on the central pool based on their project submissions or their project supply allocation. This system

[279]

BULLDOZERS AT THE ENGINEER DEPOT AT THATCHAM BEFORE THE INVASION

enabled using units to check equipment issued in the United Kingdom for completeness and workability before they departed for the Continent.7

Planning for Construction on the Continent

When PROCO projects began the ETOUSA engineers were already well aware of the problems involved in estimating materials and troop labor that would be needed for heavy construction on the Continent. Such activities normally fell into seven broad categories: ports, railways, roads, pipelines, inland waterways, utility systems, and general construction such as hospitals, shops, depots, and troop housing.8

Lacking firm plans for specific operations, engineer planners at COSSAC drew up a comprehensive list of all the engineer Class IV supplies that would be needed for a large overseas operation. The planners considered every activity that would need engineer Class IV items and set up units of supply corresponding to each activity. The set of staff tables they developed could be used to compute supplies for regular engineer operations and for the PROCO studies. The tables also proved useful to planners

[280]

ENGINEER CRANE STACKS LUMBER AT THATCHAM, APRIL 1944

of other services who wanted quick estimates of engineer work. The estimates varied greatly in kind-from requirements for a mile of railroad track to complete details for building and equipping a 1,000-bed hospital.

Even after more definite information on OVERLORD became available in July 1943, engineer planners were hampered-more than the other services-because the demand for the utmost secrecy deprived them of information on specific terrain. At the insistence of the chief engineer security was relaxed, and the details of OVERLORD were revealed in the late summer of 1943. Theoretically, planners could then study the specific ports, rail lines, and highways involved, but the need for long-range procurement action and for time to activate and train engineer units made only changing estimates possible.

Ports that could serve the Allied invaders came under close scrutiny in a series of PROCO studies. Prompted by the belief, later confirmed at Naples, that the Germans would destroy any suitable harbors to thwart Allied efforts to seize them, the engineers tried to forecast the reconstruction job expected in each port covered in PROCO planning. They continued the work of a port committee established early in 1943 under a British officer to chart the capacities of ports from the Netherlands to the Spanish border. Eventually planners included for consideration only eighteen ports in the Brittany and

[281]

Normandy peninsulas. On 12 August 1943, the ASF received an exhaustive PROCO study covering Class II and Class IV construction material and special equipment deemed necessary to reopen Cherbourg, an important objective in the final OVERLORD plan.9

When planning for specific ports proved virtually impossible without knowledge of port conditions and facilities, the engineers turned to more generalized methods of construction planning. They first correlated the planning demands to a fixed length of quay. Then, taking the OVERLORD phased tonnage requirements for the invasion, they tied the phased capacity to the figures they had derived for the fixed pier length. One ton of cargo per linear foot of pier per day became the standard engineer planning yardstick for port reconstruction. These data were combined with others to produce master lists and general requirements requisitions for the Continent.

French harbors had silted up during the enforced inactivity under German occupation, and it would take extensive dredging to clear them for the sort of supply operations envisioned in the invasion plan. The Germans were also likely to sink blockships and other obstacles in the harbor channels and alongside berthing areas: The engineers took into account the amounts of explosives or specialized equipment needed to remove the blockages. They also requested specially designed shallow-draft port repair ships, to remain under Army control, that would provide floating machine shops to maintain construction equipment in use or to make replacement parts for damaged lock gates and power plants.

The engineers attempted to develop standard, repair methods and bills of materials for the lines of communications and supply leading out of the port areas. They tabulated the labor and material needed to repair a mile of railroad track or of oil or gasoline pipeline and to provide 1,000 square feet of general-purpose shop or depot space. There were some forty-one contingency plans for dealing with unpredictable Channel tides and weather, which could make repairs necessary under other than normal water levels.

Realizing that ports would not be available for at least ninety days after the invasion, COSSAC allocated authority for beach operations among the Navy, the Army's Transportation Corps, and the Corps of Engineers, which carried the heaviest load. At this stage the main problem in planning beach supply operations was selection. Beaches had to be wide and sheltered from high winds and heavy surf. Terrain and beach outlets were of prime importance in the early days of the invasion, and the engineers tried to locate supply beaches near ports that would serve as supply arteries once beach operations closed down. Plans also included optimum sites for beach air strip construction, for inland movement and communication, for protection by Allied air power, and for limited enemy opposition.

Lines of Communications

Influenced by the widespread rail and road demolition they had met in Italy, ETOUSA engineer planners at first estimated that destruction of traffic

[282]

nets on the Continent would reach 75 percent. Since such an estimate called for staggering tonnages of railroad equipment, it was cut to 25 percent for main line tracks and to 35 to 50 percent for yards and sidings. US Army engineer and British planners provided the following revised estimates of expected damage: railroads in the port area, 75 percent; railroads up to thirty miles inland, 50 percent; those beyond that distance, 25 percent. Railway bridges in ports and up to thirty miles away would be damaged 100 percent; those beyond, 50 percent. In fact, the engineers overestimated the amount of new rail and wooden ties that would be needed in northern France. Though the destruction in major centers was severe, the trackage in open countryside escaped extensive damage, often more affected by Allied air attacks than enemy action, and cancellation orders stopped much of the continued movement of rails to Europe later in the year.

Thousands of aerial photographs helped engineer planners estimate the amount of railroad bridging that would be required on the Continent. The engineers studied track maintenance, railroad grades, the number and length of sidetracks needed, the carrying capacity of various lines, bridge capacities, water and commercial facilities, and available materials.10

The engineers' chief concern in road planning lay with maintenance rather than new construction. They generally confined estimates to maintenance of one mile of various types of roads for one month. By studying typical roadnets in other theaters, planners could obtain an average road density per square mile of territory occupied, and by computing the total area under occupation from the phase lines marked out for OVERLORD, they could calculate total road mileage during successive periods. The engineers doubted that the Germans would systematically destroy road surfaces. In the Mediterranean the Germans had limited deliberate destruction to roads in difficult terrain where repairs would constitute a major problem, and little such terrain existed in northern France.11

Tactical and highway bridging occupied much of the planners' attention. A tactical bridge policy developed in ETOUSA in April 1943 remained the basis for planning, though it changed with tactical planning. The engineers computed their requirements for highway bridges by using aerial photographs, expecting to use standard 35-ton capacity steel treadway to bridge the thirty- to sixty-foot gaps anticipated on the Continent. In the theater, the engineers used Bailey bridging for everything from tactical floating spans to lines of communications bridges for army and division use. But ongoing theater planning coincided with a search for new models of tactical bridging in the United States necessitated by new, wider replacements for the M-4 Sherman tank and by Army Ground Forces demands on

[283]

the Engineer Board for a complete revision in floating bridge equipage. Testing of new prototypes and of new Bailey bridging applications continued into early 1944. Thus, as late as January 1944, many engineers in the United States were still considering the Bailey strictly as a line of communications bridge while engineers in the ETO, remembering the Italian campaign, favored its use in any tactical situation to which it could be adapted.12

Initial estimates on the consumption of gasoline in the ETO were indefinite; only late in the planning stage were engineer planners able to make fairly accurate calculations. Except for bulk storage installations, which were usually in the vicinity of ports, existing POL facilities generally lay underground and were not well suited to military needs. Pipelines had to be laid along existing roads to minimize the problems of transporting and distributing construction materials. The terrain along selected routes was an important factor, for it had a direct bearing on the number and spacing of pumping stations. The tactical plan and the location of large supply depots generally would determine both the location and capacity of bulk storage installations. Thus, with every major change in the tactical plan (or with any other material change in plans) a new pipeline distribution system had to be designed.

Ship-to-shore pipelines also posed a difficult problem. Assurance was needed that pipeline distribution of liquid fuels could be undertaken before a port was available. A method had to be devised to permit tankers anchored one-half to one mile off the beaches to discharge their contents directly into a shore-based distribution system. After experimenting, American and British forces adopted a simple British solution. A small vessel with powerful winches such as a submarine-net tender could pull successive lengths of rigid pipe seaward from a beach. A flexible buoyed hose attached to the seaward end of the pipe would permit direct discharge of tankers into the system.13

The engineers could not estimate in advance requirements for the reconstruction of the inland waterways of northeast France and Belgium, which the Germans were using extensively, for there was no standardization in their dimensions or in their equipment. Many were the product of centuries of development of internal communications. Except for lock structures, reconstruction would be largely an earthmoving job requiring the type of equipment organic to engineer construction units. The repair of locks and lockgates, the engineers believed, could be accomplished by improvisation using local materials.14

The major problem the engineers faced with utilities systems on the Continent was determining civilian needs-military requirements were to be met by self-contained utilities provided for all new camps and hospitals. Planners gathered population statistics and per capita figures on water consumption and electric power. They established

[284]

minimum standards for civilian use and studied existing utilities systems and anticipated damage.

In the end the engineers regarded the PROCO system as problematic, either as a means for estimating necessary theater stocks accurately or as a supply system. Though PROCO studies were an obvious method of drawing up broad estimates and planning requirements for construction on the Continent, there was no possibility of pinpointing engineer requirements under PROCO or any other system. While their objectives were still in enemy hands the engineers could only guess at the type and amount of materials they would need. They also had a problem in estimating the requirements of major field commands that had not yet arrived in England. First Army headquarters came only in October 1943, and the engineer planners had to calculate the field army's necessities anew. Nor did PROCO reduce the time it took for material to move through the supply pipeline to the theater. In the opinion of the theater engineer, the projects "proved to be a poor device for obtaining supply action."15

Responsibility for Civilian Labor

By early 1944 theater planners had tentative outlines for tapping the wealth of civilian labor on the Continent. SHAEF established a Combined Military Procurement Control as an executive agent for General Eisenhower in matters of local supply procurement and civilian hiring for both British and American forces. Overall American theater-level planning for employing civilians abroad was the job of the theater general purchasing agent, who delegated his authority among various levels of the projected Communications Zone command that General Lee would head on the Continent. On 19 April 1944, Lee formally gave responsibility for managing the procurement of civilian labor in the field to the engineers since they would be the first to need workers for beach dumps, ports, storage areas, and roadnets. Maj. Gen. Cecil R. Moore's staff had no plans for this eventuality, few qualified officers or enlisted men to run a personnel clearinghouse, and no understanding of the problems of pay levels, housing, and welfare of civilian workers. Despite repeated effort to get engineer officers who could handle the job, the civilian labor responsibility fell to the theater engineer's administrative division. Actually, the engineer-spawned Civilian Labor Procurement Service had assigned members of other technical services who could screen prospective employees for specialized work. The general purchasing agent, privy to the highest counsels of the Allied command on the subject of civilian workers in the Combined Military Procurement Control, coordinated activities from the theater command level. SHAEF retained the final say in matters of pay and set wage tables keyed to prewar salary levels in given geographic areas.16

[285]

The engineers set broad classifications to delineate conditions of employment and skill levels for workers. Two general categories aligned prospective employees by their willingness to work in mobile or static detachments. Static laborers usually worked in a single location, lived nearby, and were responsible for their own quarters and food. Mobile workers, who received their sustenance and housing from the Allied command employing them, usually performed as part of a transient labor company organized on military lines. Both static and mobile workers served under contract and were considered unskilled until they proved otherwise. Their wages would then change accordingly.

The foundation for regional and local management of labor offices also came into being before the invasion. Each base section was to have a procurement office, and in each French region there would be a representative in a centrally located major city. The first organization was scheduled for the immediate invasion area, and plans called for offices in Ste. Mere-Eglise, Longueville, Carentan, Bricquebec, Cherbourg, Isigny, and UTAH Beach.17

Refinements in OVERLORD's Operation

Tactical command for the invasion consisted of a three-phased allotment of responsibilities to the higher headquarters arriving in Normandy to control the incoming combat and support units. In the assault phase, the US First Army and the British Second Army operated separately to consolidate the beaches under the remote command of the British 21 Army Group. Phase II would begin when 21 Army Group came ashore and assumed tactical control of both field armies. Until the second stage was concluded First Army and all the incoming service troops attached to it were under 21 Army Group control. The last invasion phase foresaw the introduction of another American field army, the Third, and of the American 1st Army Group headquarters. General Sir Bernard L. Montgomery, commanding the 21 Army Group, was responsible for SHAEF tactical planning, but he relied heavily on American contributions to the NEPTUNE plan which referred to actual operations under the OVERLORD invasion plan. Though the 1st Army Group headquarters was involved in this process, Montgomery also delegated the planning for the actual assaults to the First Army staff.18

Detailed planning for supply and for rehabilitation of Continental ports and rail and roadnets fell to two new organizational echelons established to smooth the transfer of supply and administrative functions across the English Channel. Fifth Army in Italy had briefly but successfully experimented with an advance supply section at Naples to eliminate the long and uncontrollable supply lines that had become necessary in North Africa. In December 1943 COSSAC established a similar section to relieve First Army of supply responsibilities immediately behind its area of operations in the first days of the invasion. Formally in existence after 7 February 1944, Headquarters, Advance Section, or ADSEC, was under the command

[286]

of Col. Ewart G. Plank, an engineer officer who had commanded Eastern Base Section. The ADSEC engineer was Col. Emerson C. Itschner. The section was to remain attached to First Army in the American chain of command and be responsible for supply installations behind it until the arrival on the Continent of a second, higher command, Forward Echelon, Communications Zone. Forward Echelon, also in existence under ETOUSA since 7 February, was formally established by SHAEF directive two days later. Designed as an extension of General Lee's SOS organization and equipped to run the communications zone in France until the entire SOS moved across the Channel, the command, known as FECOMZ, would become ADSEC's parent as soon as General Bradley drew a rear boundary for First Army. Planning proceeded under Col. Frank M. Albrecht, General Moore's former plans officer, as chief of staff. On 14 March 1944, Brig. Gen. Harry B. Vaughan, former commander of Western Base Section, took over FECOMZ.19

First Army was to estimate the tonnage and supply needs from D-day to D plus 15 (Phase I) for all US forces, including air and naval forces in the assault, and have ETOUSA fill the requisitions. In Phase II, D plus 16 to D plus 40, 1st US Army Group was to compile the required tonnage figures but would have ETOUSA fill the requirements through ADSEC. FECOMZ was to arrange for the buildup to COMZ and to introduce base sections at the same time that 1st Army Group was strengthening the combat zone with additional armies. Between D plus 41 and D plus 90 (Phase III), 1st Army Group would continue to assemble the overall tonnage requirements, but they would be implemented through FECOMZ, which would assume active control when a second base section arrived on the Continent and ADSEC moved forward with the armies. Not until D plus 90 was COMZ to reach the Continent and take over from FECOMZ.

Whereas First Army issued its plans in February 1944, the FECOMZ plan was not complete until 30 April 1944. The detail involved in some aspects of the planning was enormous, and the ADSEC engineer plan literally outweighed that of all the other technical services combined. Two thick volumes of data on the Normandy ports included an analysis of each port's facilities, a schedule of reconstruction, and a catalogue of equipment and materials required.

Planning for post-OVERLORD operations (D plus 90 to D plus 120) forced Moore, along with other technical service chiefs, to furnish an estimate-by month and class-of the tonnages he would need for the entire period from D plus 90 to D plus 360. Planning for this period continued under the PROCO system according to ETOUSA SOS Series H directives. Two directives before D-day established progressive phase lines and troop counts to D plus 360 and required engineer statements on which material was to be stored in the United Kingdom and which would go directly to the Continent.

A British officer, Maj. Gen. H. B. W. Hughes, headed the SHAEF engineer division, but he had an American deputy,

[287]

Brig. Gen. Beverly C. Dunn, and the four branches under Hughes were also headed by Americans. The division's chief task was to coordinate the work of the army group engineers and to provide terrain and engineer intelligence studies; recommendations on new techniques, equipment, and tactics; and engineer estimates of the situation. Perhaps the most important feature of this high-level assistance was anticipating what engineer supplies the army groups would need and helping to obtain them from Allied supply organizations.20

Joint Stockpiling With the British

Because OVERLORD was an Allied undertaking, a system of combined supply or joint stockage was desirable to prevent overprocurement of interchangeable items; to ensure sufficient supply where procurement was difficult and it was unclear which force would employ the item; and to provide items that would, in fact, serve British and American forces simultaneously joint stockpile items included Bailey bridges and railroad and port construction equipment. Some parts of such items were manufactured in the United Kingdom, others in the United States. The British were responsible for procurement of some items, turning over to American forces their share; others the Americans procured and divided with the British.21

Planning for the joint stockpiling of railroad items began in the summer of 1942 when the Transportation, Plant, and Personnel (TPP) Section of SOS, ETOUSA, was formed with both US and British members under a central planning staff. This group included a representative from the Corps of Engineers. At the time railway planning started no standard US military railroad bridge had been developed, and it became necessary to adopt those the British had. Since the British were unable to produce enough bridges for both armies, the TPP Section arranged for production of the same types in the United States and ensured that they were interchangable with those manufactured in Britain. Later agreements provided that stockpiles would be divided equally between American and British forces and that any reallocation would be the responsibility of an Allied headquarters.22

During the summer of 1943 the British repeatedly tried to broaden the base for joint stock items, which had been limited to items for joint use or for provision of a joint service. US engineers objected strenuously to these efforts and, after long discussion, won their point. The British had argued that most engineer requirements should be calculated jointly and the supplies handled in joint stockpile. Some British agencies even proposed that they handle procurement of all such items, whether they came from the United States or the United Kingdom. These proposals were hardly advantageous to the US

[288]

Army, for if pooling American and British resources meant absorbing American personnel into British operations, American engineers would be deprived of much-needed experience in doing their job independently according to their own procedures.23

With the establishment of COSSAC, joint policies and procedures were defined. A COSSAC circular issued on 25 June 1943 required written provisions for joint stockpiles and COSSAC approval for talks between American and British counterparts. SOS, ETOUSA, further clarified the issues in August, September, and November 1943. Allied commands could jointly stockpile items only if definite economies would result during the period when forces on the Continent would be supplied principally from the United Kingdom. Later, American policy required that, except for agreements already made, joint stockpiling with the British would be discontinued; no further agreements were to be made after 21 November 1943. This decision came almost simultaneously with a PROCO pronouncement calling for firm plans for PROCO supplies for the first 240 days after the invasion. Since the PROCO items were in addition to the US share of joint requirements, the Americans had to order them inaependently.24

Training

Most engineer units arriving in the theater in 1943 and early 1944 needed considerable training. Camouflage units arriving in the United Kingdom were unfamiliar with the most important equipment they were to use on the Continent. General service regiments needed to learn about mines and booby traps and the uses of Bailey bridges. Engineer combat battalions lacked training in recording minefields and repairing roads. Drivers and mechanics of dump truck companies had trained with non-TOE vehicles. Port construction and repair units had trained in the United States with different types of equipment than those they received in the United Kingdom. The one notable exception was the topographic organizations, which arrived well trained for their work on the Continent.25

Training SOS engineers in the United Kingdom was the responsibility of Troops Division, OCE, ETOUSA, which had a London branch planning for future operations and a Cheltenham branch providing training aids to SOS troops and supervising SOS engineer schools. The base section supervised training. Theoretically one hour a day or one day a week was given over to training for future operations, but construction priorities often made it impossible to follow any training schedule. Troops might be working on day and night shifts, or bad weather would intervene and training would have to be canceled. In any case, the allotted one hour a day was of little use, for it often took that long to reach a training area.

[289]

MODELS OF BELGIAN

GATES, patterned after German obstacles on

Normandy beaches.

Limiting the training time to an hour also meant that a subject had to treated completely in that time, for it often proved impossible to continue a subject during the next training period. When longer lapses occurred between sessions, men forgot subject matter and continuity was destroyed. (Map 14)26

In March 1944 when extensive training opportunities became possible, Troops Division, OCE, ETOUSA, suggested one to two months for many units. Full-time training was frequently more arduous than construction work. Often the day's schedule was extended from 10 hours to 12-15 hours so that the troops could practice techniques used in night operations. Considerable time also had to be devoted to basic subjects that had been forgotten or only infrequently put to use.27

Virtually every type of military subject was available. The American section of the British School of Military Engineering included courses in mines, booby traps, demolitions, Bailey

[290]

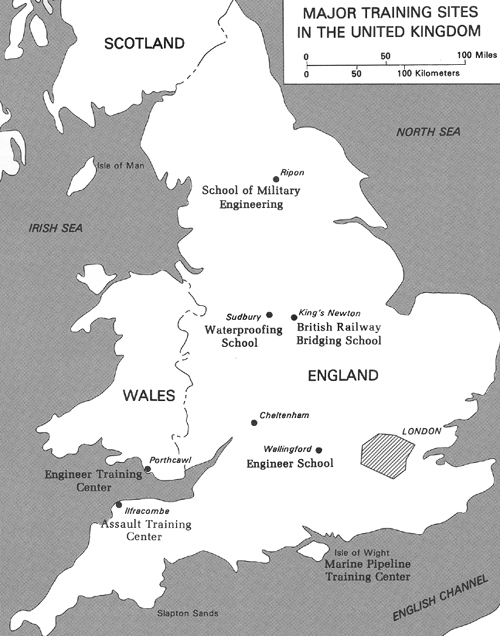

WIRE ENTANGLEMENTS AND DRAGON'S TEETH at the Assault Training Center, Woolacombe.

bridging, camouflage, waterproofing, and airfield engineering and reconnaissance. A port construction and repair training center in Wales specialized in construction of V-type trestles, Baileys, wooden trestle bridges, Sommerfeld mats, and tubular scaffolding. On the Isle of Wight the engineers conducted marine pipeline training. A five- to seven-week course at the Transportation Training Center trained general service regiments for railroad work, especially railroad bridging.28

ETOUSA conducted courses in mess management, fire fighting, cooking, motor transport, enemy personnel and equipment identification, basic radio operation, gas warfare, and waterproofing. At the engineer section of the American School Center, run by G-3, ETOUSA, the primary objective was developing physical stamina and endurance necessary for combat while providing three months of basic technical and tactical training. Officers and enlisted men attended a two-week course in logistical planning at the British Air Ministry's joint British and American School. Engineers could attend schools offering instruction in quartermaster transport, bomb reconnaissance, field

[291]

MAP 14

[292]

artillery (for antiaircraft fire), landing craft loading, bituminous paving and road construction, troop leadership, enemy document evaluation, and order of battle.29

Engineers took a leading part in the well-known Assault Training Center. Col. Paul W. Thompson, an engineer officer, commanded the school from 2 April 1943 until early March 1944. Thompson and his staff spent April and May 1943 studying the French coastline. They calculated that at no place along the coast of northwest France could the Germans use more than one platoon per 2,000-2,500 yards to protect beach fortifications. They deduced that Germans would have extremely strong field defenses with concrete pillboxes, emplacements, and shelters, and thinly spread defenders providing considerable automatic fire. The Assault Training Center prepared units to deal with such a defensive strategy. Set up on the northwest coast of Devonshire at Ilfracombe, the center was completed in March 1944, allowing over two months before the invasion for unit training and a series of full-scale exercises. Engineer units constructed and placed beach and underwater obstacles (modeled after those on the beaches of northern France) and gave lectures on a number of subjects connected with an assault landing.30

The British contributed in many ways to training, opening their schools to American engineers and offering ideas and equipment. British and American units exchanged parties, usually composed of one officer and ten enlisted men, for fifteen days. Each group learned the characteristics, methods, weapons, tools, nomenclature, problems, and tactics of the other. The practice also increased understanding and comradeship between Allies.31

First Army's training emphasized bridge building, road maintenance- and construction, mine placement, and enemy mine detection and removal. First Army also recommended that all company grade engineer officers receive instruction in adjusting artillery fire by using forward observation methods. Engineer units used schools, lectures, and demonstrations to train their own men and sent enlisted men and officers to schools in higher British or American echelons.32

American corps and divisions trained units for special missions in the assault. Engineers practiced the rapid construction of plywood treadway bridges mounted on pneumatic floats for crossing flooded areas and absorbed whatever they could on terrain problems to be expected on the Continent.33

Maps for the Invasion

US and British military forces could

[293]

ENGINEER MAPMAKER USES A MULTIPLEX to establish accurate contours on invasion maps.

be proud of the maps they prepared jointly for operations on the Continent. In 1939 the British had had to start almost literally from scratch. Only for eastern France were World War I maps available on a scale as large as 1:25,000; few of them had been revised to show roads, bridges, or railroads built since that time or changes in fields and woods. For western France the only military maps were based on those Napoleon had used. They had been edited and enlarged to a scale of 1:50,000 but had not been made more accurate. Few maps had had any terrain corrections since 1900.

Shortly after the evacuation of Dunkirk in 1940 the British Army inaugurated the Benson project, named for an airfield in Oxfordshire. From this airfield Royal Air Force (RAF) planes took off to map the French coast from Cherbourg to Calais and an area extending inland approximately sixty miles; the British succeeded in producing 1:25,000 scale maps.34 Early in 1942, in accordance with the terms of the Loper-Hotine Agreement, the British assumed general mapping responsibility for most of western Europe. Americans helped in taking aerial photographs for mapmaking and reproducing maps for use by US forces.35

[294]

General mapping (as distinguished from "intelligence" mapping of individual spots) began with aerial photographs showing roads, streams, railroads, bridges, buildings, fields, woods, and flood areas. Using the aerial photograph, mapmakers drew with instruments a topographic contour, or "topo map," divided into small military grid squares that enabled the user to locate areas exactly. When manpower or time did not permit making topo maps, the original photograph could be made to serve as a map by the application of grid lines, contours, place names, and indications of scale and direction. The poor quality of many photomaps prejudiced the users against them, but the chief engineer saw their value in alleviating the burden on mapmakers and aerial photographers and planned to use photomaps in the preinvasion period.36

Topo maps of 1:25,000 scale were produced from aerial photographs taken with a six-inch metrogen lens with high-speed multiplex equipment which registered both horizontal and vertical dimensions of terrain features. Production of these maps was the primary mission of the base topographic battalion, the most important element in the ETO topographic service. Each base topographic battalion contained a photomapping company that had a complete set of multiplex equipment including approximately one hundred projectors, enough to put fifty operators to work after the aerial triangulation and control extensions were finished. A photomapping company, working with good quality aerial photography, could map approximately one hundred square miles a day.37

Until the summer of 1943 the greatest hindrance to mapmaking in the European theater was the difficulty of obtaining good aerial photographs to work with-a responsibility of the Army Air Forces. After four special B-17E photographic aircraft sent to the ETO in the fall of 1942 were diverted to North Africa, the British gave an RAF reconnaissance squadron the job of filling US photographic mapping needs. By May 1943 this squadron had photographed some 22,000 square miles of the first-priority area. But because the RAF used a type of camera not suited to American equipment, fewer than 10,000 square miles of large-scale topo maps had been produced. The US Army Air Forces had not helped, mainly because the AAF's Director of Photography, Lt. Col. Minton W. Kaye, then in the ETO, felt that the hazards and costs of securing wide-angle vertical photography over heavily defended areas were too great. He advocated a system of aerial photography known as trimetrogen photography. Developed for small-scale aeronautical charts, the system used wide-angle cameras that tilted in divergent directions to produce one vertical and two high oblique photographs which made a composite picture of an area from horizon to horizon. The engineers objected to trimetrogen pictures because oblique photography multiplied the difficulties of making enlargements and produced

[295]

distortions that no known instrument could correct.38

In June 1943, General Moore, Col. Herbert Milwit, head of Moore's intelligence division, and Maj. Gen. Ira C. Eaker, commanding officer of the Eighth Air Force, discussed the problem. General Eaker said he would help the engineers get more accurate photos. Beginning on 22 June 1943, the 13th Photo Squadron, using K17 cameras in F-4 and F-5 aircraft-reconnaissance versions of the P-38 Lightning-took wide-angle photographs covering more than 10,000 square miles without any loss from enemy action. The success of this project promoted greater Air Force-engineer cooperation, and there was no serious shortage of aerial photography during the invasion and for several months thereafter.

US support of the Benson project began early in 1944. Using aerial photography sent from England, the US Geological Survey and the Tennessee Valley Authority, on assignment from OCE, prepared 200 sheets at the 1:25,000 scale covering 16,000 square miles of northern France. To enable the mapmakers to meet deadlines for the Normandy landings, the OCE Intelligence Division permitted the omission of much fine detail such as hedgerows but backed up each battle map with a photomap of the same area.39

In assuming responsibility for providing engineer intelligence as well as topographic service, General Moore was treading on new ground. No background of intelligence experience existed in the Corps of Engineers equivalent to that acquired in construction engineering on rivers and harbors duty. Few officers were competent to handle the expanded duties in engineer intelligence and topography, nor was any precedent available upon which to base an effective organization or plan. By agreement with a succession of theater G-2s, General Moore gave the Intelligence Division, OCE, ETOUSA, responsibility for all problems pertaining to the topographical service, including map policy, theater map library operation, and planning for map production, reproduction, supply, and distribution.

In planning map production the Intelligence Division had to consider what map series should be completed, which maps the forces involved would need, how much time was available, and which cartographic and reproduction facilities could be used in the field. Planners soon realized that the required maps could not be produced with the available facilities in the time remaining. They decided to put first priority on 1:25,000 maps and photomaps of France north of the Loire and west of the longitude of Paris, with all new maps of the same design; second priority on 1:50,000 maps of the coastal regions in the invasion area; third priority on 1: 100,000 series covering the entire operational area; and fourth priority on a 1:200,000 road map. A more satisfactory 1:250,000 map suitable for both ground and air use was also required; the 1: 1,000,000 series needed considerable revision; and many town plans-several thousand sheets-had to be produced.

The expectation that the British War

[296]

Office's Directorate of Military Survey could provide most of the maps that US forces in Europe would need soon had to be abandoned. Computations in 1943 indicated that the four US armies planned for European operations would need 7 million maps a month, more than base and field topographic units and local civilian facilities could provide. To produce that many maps, 35 million impressions would have to be made, one for each of the five colors needed for the average map. As- this was beyond British capability, in mid-December 1943 Col. Herbert B. Loper of OCE, WD, arranged for the United States to assume a large share of supplying American forces. For security reasons British and American facilities located in England would provide maps needed from D-day to D plus 90. After D plus 90 all maps for US forces would be produced in the United States except those required for special, unanticipated, or highly classified projects. Army Map Service (AMS) received the first monthly requisition in April 1944 and was ready with the first shipment in July. Eventually, out of every ten maps used in the theater Army Map Service and private contractors in the United States printed four; the British, the overseas topographic units, and the French National Geographic Institute, six.40

November 1943 plans for map service in support of the tactical forces provided one topographic battalion for each army group and each army and one company for each corps and air force. Realizing the need to strengthen staff control of these units, General Moore recommended adding topographic sections to the engineer headquarters of army groups and armies. His proposal could not be put into effect because of the time it took to obtain theater approval; therefore, he provided each of the four armies planned for European operations with an engineer survey liaison detachment of five officers and ten enlisted men to handle the topographic service. This improvisation worked well and in his opinion "probably meant the difference between outstanding success ... and a rather dismal failure." He later came to feel that a topographic officer should also be added to the corps engineer staff.41

The topographic battalions and companies were well organized and well equipped, except for map distribution, a problem that the War Department and ETOUSA had neglected. Experience showed that maps could not be handled in the same way as other Class IV items, for they were too closely related to tactical operations. Distribution had to respond immediately to changes in tactical plans, and a constant flow had to be maintained. Maps were so bulky that stocks to cover any contingency for a ten-day period would weigh at least sixty pounds-too much for an officer to carry on his person. Moreover, the transportation of stocks between depots and from depots to troops was to cause more trouble than any other aspect of map distribution on the Continent.42

Security of maps was all important in the OVERLORD planning stage. The maps were sealed in coded bundles from which individual maps could be

[297]

drawn without revealing much about the general plan for any given area. On 1 September 1943, the British Directorate of Military Survey and General Moore's Intelligence Division agreed to establish four special simnel depots, named for the code system applied to the map bundles. The depots, located at Aldershot, Oxford, Reading, and Towchester, had identical stocks, the code keys for the maps being kept by a minimum number of officers. In late 1943, only the Oxford simnel depot had American personnel, but as the American invasion forces outnumbered the British in May 1944 the US Army took over a second facility at Lockerley.

The United States also had a depot at Witney, set up in March 1944 with bulk stocks for the Continent; one at Reading, opened in January 1944 with reserves for the Air Force; another at Cheltenham, organized in September 1942 to store maps for use in the United Kingdom; and a fourth at Swindon, established in January 1943 with bulk stocks of United Kingdom and Air Force maps. From Cheltenham and Oxford the maps went to the marshaling area mapping depots, then to camp commanders who undertook detailed distribution. Maps for troops in the marshaling areas were under guard at all times before they were issued to individual troop units and during movement from depots to camps had a guard detail of an officer and several armed enlisted men. When any coded rolls (packages of twenty and fifty maps) were opened in a depot, all persons handling the maps were locked into the storage buildings under strict security control.43

In mid-1943 as forces massed in the United Kingdom to prepare for the invasion of France, attention also turned to specific landing places for the assault force. The engineering problems associated with getting the troops across the mined and defended beaches were in themselves immense; organized and rapid supply movement across the same terrain was essential to the success of the operation. It was clear that engineers would be in plentiful evidence on the D-day beaches.

[298]